Global Recognitions

Social compliance is significant matter to any retailers, it's in our

professional commitment to have the responsibility to offer workers a reasonable salary,

safe workplace, and harmless environment to perform operations. We've joined the Recycle

Claim Standard (RCS) in 2019 when we recognized carbon release reduction is one of a

society responsibility as manufacturer.

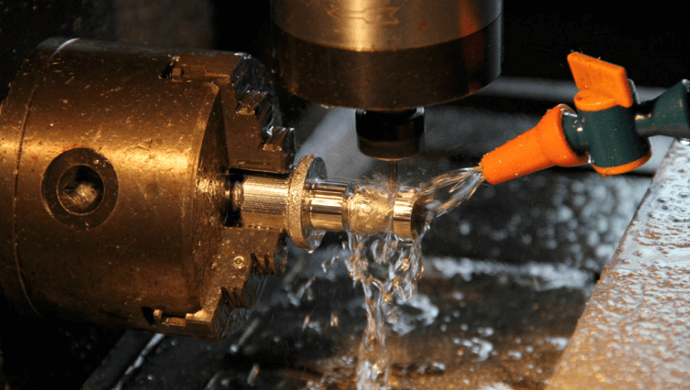

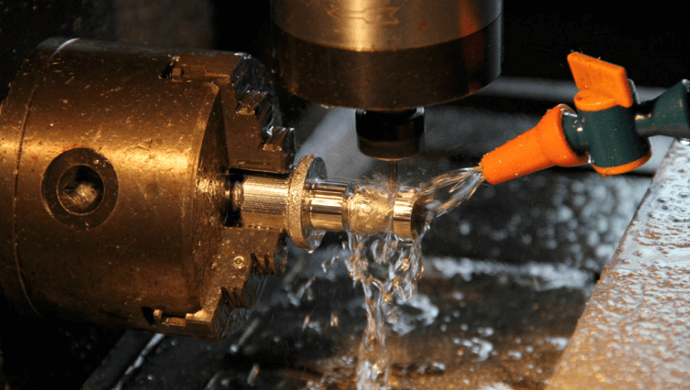

We set up an exclusive jewelry line made of recycle material. As for now,

we are covering major materials such as zinc, steel, copper, brass, and sterling silver.

Our pace of carbon reduction never stops since then, with the extension of dead stock

materials dead.